PRODUCT CENTER

CONTACT US

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

Mobile

White corundum

Classification :

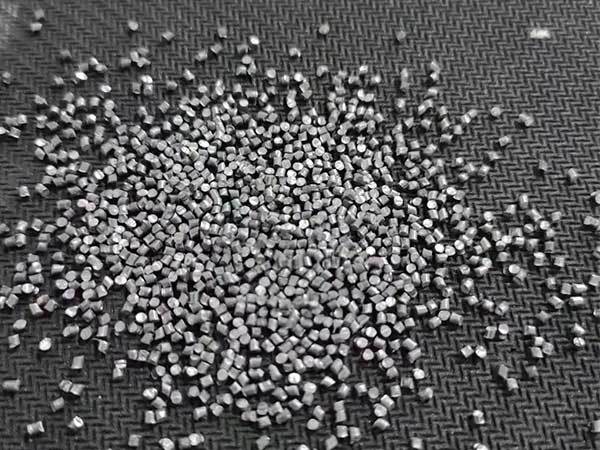

key word : Grinding pellets

Product Details

Product Details

White corundum is made from industrial alumina powder, which is smelted in an arc at a high temperature of more than 2000 degrees and then cooled. It is crushed and shaped, magnetically separated to remove iron, and screened into various sizes. It is suitable for the manufacture of ceramics, resin-bonded abrasive tools, grinding, polishing, sandblasting, precision casting (corundum for precision casting), etc. It can also be used to manufacture advanced refractory materials. The code "WA" is consistent with international general standards and national standards. , most of them are for export, and a certain amount is also supplied to domestic users.

Product Parameters

|

Purpose |

Specifications |

Main Chemical % |

|||

|

|

|

Al2O3 |

Na2O |

Magnetic% |

SiO2 |

|

Abrasive |

F12#—80# |

≥99.2 |

≤0.4 |

— |

≤0.03 |

|

|

90#—150# |

≥99.0 |

≤0.4 |

≤0.03 |

≤0.05 |

|

|

180#—240# |

≥98.5 |

≤0.4 |

— |

≤0.03 |

|

|

1#-63# |

≥99.3 |

≤0.4 |

≤0.03 |

≤0.05 |

|

Refractory |

180#—0 |

≥99.3 |

≤0.4 |

≤0.06 |

≤0.05 |

|

fine powder |

0-1mm |

≥99 |

≤0.4 |

≤0.1 |

≤0.02 |

Applications

White corundum abrasive is suitable for surface beautification of various high-end products, crafts or hardware. After sandblasting, the surface is white without any impurities, eliminating the trouble of cleaning. Fine white corundum can be used as the head of polishing and grinding. It can also be used as various product additives. It can be used for solid and coated abrasives, wet or dry or blasting sand, suitable for ultra-fine grinding and polishing in crystal and electronic industries, and for making advanced refractory materials. It is suitable for processing hardened steel, alloy steel, high-speed steel, high-carbon steel and other materials with hard hardness and high tensile strength. It can also be used as catalyst, insulator and precision casting sand. Derusting, decontamination, and scale removal of iron workpieces to increase the adhesion of coatings and coatings; descaled aluminum workpieces, surface strengthening, and polishing effect; descaled matte effect of copper workpieces, and crystal frosting of glass products , Engraved pattern plastic products with matt effect, denim and other special fabrics plush processing and effect patterns

1. Surface processing: metal oxide layer, carbide black skin, metal or non-metal surface rust removal, such as gravity die-casting mold, removal of oxide or release agent of rubber mold, black spot on ceramic surface, uranium color removal, color painting rebirth.

2. Beautification processing: matte or matte processing of various gold, K gold jewelry, precious metal products, matte processing of crystal, glass, corrugated, acrylic and other non-metals, and can make the surface of processed objects metallic luster.

3. Etching processing: jade, crystal, agate, semi-precious stones, seals, elegant stones, antiques, marble tombstones, ceramics, wood, bamboo and other etching art.

4. Pre-processing: Teflon (TEFLON), PU, rubber, plastic coating, rubber roller (ROLLER), electroplating, metal spray welding, titanium plating, etc., to increase the surface adhesion.

5. Burr processing: burr removal of bakelite, plastic, zinc, aluminum die-casting products, electronic parts, magnetic cores, etc.

6. Stress relief processing: Stress relief processing for aerospace, national defense, precision industry parts, rust removal, paint removal and matting, refurbishment, etc.

APPLICATION AREA

Oil Pipeline

Oil Pipeline

Steel Plate

Steel Plate

Casting

Casting

Aerospace

Aerospace

Car

Car

Ship

Ship

Steel Structure

Steel Structure

Casting

Casting

RELATED PRODUCTS

GET A FREE QUOTE

To: Shandong HengSin Industry Produts Co,Limited