PRODUCT CENTER

CONTACT US

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

Mobile

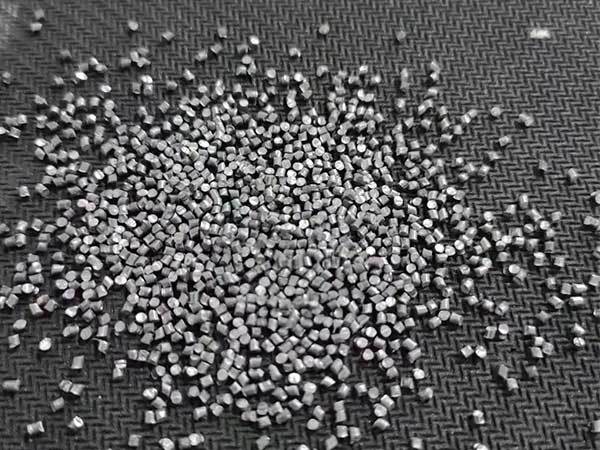

Grinding pellets

Classification :

key word : Grinding pellets

Product Details

Product Details

The grinding shot implements the steel wire cut shot standard---JB/T8354-1996, which has the advantages of steel wire cut shot, and also has the following characteristics:

1. Appearance

Grinding pellets should be oval, and the number of ultra-long and flat flake particles in the finished product should not exceed 10% of the inspected amount;

2. Specifications

The specification range of grinding pellets is 0.6#, 0.8#, 1.0#, 1.2#, 1.4#, 1.7#, 1.8#, 2.0#, 2.4#.

3. Technical requirements

|

Chemical Composition |

C |

Si |

Mn |

P |

S |

|

Content |

0.65-1.10 |

0.8-1.65 |

1.20-2.0 |

<0.05 |

|

4. Hardness

HRC of grinding pellets: 50-65 (not tempered) HRC: 40-50 (tempered)

5. Metallographic organization

The metallographic structure of the grinding pellet is tempered martensite, tempered troostite

6. Cracks

Grinding pellets with cracks shall not exceed 3% of the inspected amount

7. Physical properties

The willfulness of the grinding pellet is I, and the tensile strength is 1520N/m㎡

Applications

At present, in the fields of automobile, motorcycle and other parts finishing, grinding steel shot is the mainstream metal grinding material of choice, with good grinding effect.

Due to the fine manufacturing process of the grinding shot, the products produced have very uniform particles. Because the grinding shot has a mature and standard production process, there are absolutely no pores inside the grinding steel shot, and it has a long service life. The finished product has a short time and high production efficiency. It is generally used in the industry to quench gears, screws, springs, chains, various stamping parts, standard parts and stainless steel and other workpieces with high hardness. It can achieve surface descaling and surface strengthening. Treatment, smoothing, paint stripping, anti-corrosion, dust-free spray finishing, strengthening the surface of the workpiece to highlight the metal color of the product, so that it can achieve satisfactory results.

Grinding steel shot is the first choice for hardening treatment of various metal materials. Today, with the continuous development of the market, the demand in the field of "high, precise and sharp" is also growing. These needs require high science and technology to support, and then mechanical The requirements for surface cleaning of products are also getting higher and higher. On the other hand, with the development of science and technology, China's market competitiveness has become more and more intense. In order to improve their production efficiency and increase profits, everyone is actively reducing costs and improving product quality to ensure their own market. Competitiveness, expand our market share, grinding steel shot is the most ideal shot blasting material developed in response to market demand, grinding steel shot is a truly environmentally friendly shot blasting material!

APPLICATION AREA

Oil Pipeline

Oil Pipeline

Steel Plate

Steel Plate

Casting

Casting

Aerospace

Aerospace

Car

Car

Ship

Ship

Steel Structure

Steel Structure

Casting

Casting

RELATED PRODUCTS

GET A FREE QUOTE

To: Shandong HengSin Industry Produts Co,Limited