PRODUCT CENTER

CONTACT US

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

Mobile

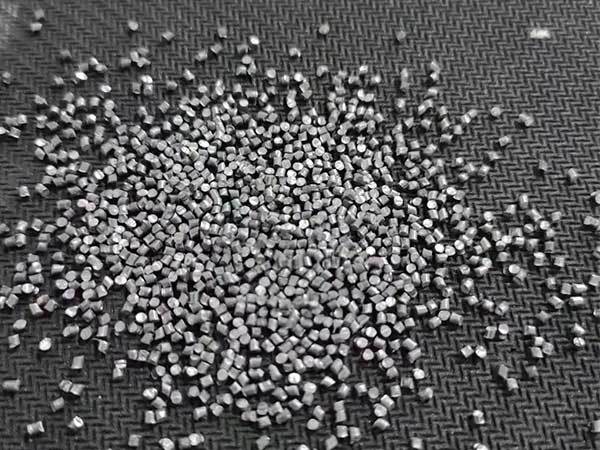

Grinding pellets

Classification :

key word : Grinding pellets

Product Details

Product Details

Brown corundum is made of bauxite and coke (anthracite) as the main raw materials, and is smelted at high temperature in an electric arc furnace. The abrasive tools made of it are suitable for grinding metals with high tensile strength, such as various general steels. , malleable cast iron, hard bronze, etc., and can also manufacture advanced refractory materials. Brown corundum has the characteristics of high purity, good crystallization, strong fluidity, low coefficient of linear expansion and corrosion resistance. It has been verified by dozens of refractory production enterprises that the product has the characteristics of no explosion, no pulverization and no cracking during the application process. In particular, it is much more cost-effective than traditional brown corundum, making it the best aggregate and filler for brown corundum refractories.

Product Parameters

Note: F is the specification for bonded abrasives and sandblasting

P is the specification for coated abrasives

W is micro powder, 320# is W40

|

Purpose |

Specifications |

Main Chemical % |

Magnetic% |

||||

|

|

|

Al2O3 |

Fe2O3 |

SiO2 |

TiO2 |

|

|

|

Abrasives |

F |

4#—80# |

≥95 |

≤0.3 |

≤1.5 |

≤3.0 |

≤0.05 |

|

|

|

90#—150# |

≥94 |

|

|

|

≤0.03 |

|

|

|

180#—240# |

≥93 |

≤0.3 |

≤1.5 |

≤3.5 |

≤0.02 |

|

|

P |

8#—80# |

≥95.0 |

≤0.2 |

≤1.2 |

≤3.0 |

≤0.05 |

|

|

|

100#—150# |

≥94.0 |

|

|

|

≤0.03 |

|

|

|

180#—220# |

≥93.0 |

≤0.3 |

≤1.5 |

≤3.5 |

≤0.02 |

|

|

W |

1#-63# |

≥92.5 |

≤0.5 |

≤1.8 |

≤4.0 |

— |

|

Refractory |

Sand |

0-1mm 1-3mm 3-5mm 5-8mm 8-12mm |

≥95 |

≤0.3 |

≤1.5 |

≤3.0 |

— |

|

|

|

25-0mm 10-0mm 50-0mm 30-0mm |

≥95 |

≤0.3 |

≤1.5 |

≤3.0 |

— |

|

|

fine powder |

180#-0 200#-0 320#-0 |

≥94.5≥93.5 |

≤0.5 |

≤1.5 |

≤3.5 |

— |

|

|

|

|

|

|

|

|

|

Applications

Brown corundum is called the teeth of industry: mainly used in refractory materials, grinding wheels, sandblasting.

1. It is used to manufacture advanced refractory materials, castables, refractory bricks, etc.

2. Sandblasting - moderate abrasive hardness, high bulk density, no free silica, large specific gravity, good toughness, it is an ideal "environmental" sandblasting material, widely used in aluminum profiles, copper profile glass, washed jeans Precision molds and other fields;

3. Free grinding - grinding grade abrasives, which are used in free grinding in the fields of picture tubes, optical glass, single crystal silicon, lenses, watch glass, crystal glass, jade and other fields.

4. Resin abrasives - abrasives with suitable color, good hardness, toughness, suitable particle section type and edge retention, applied to resin abrasives, the effect is ideal;

5. Coated abrasives - abrasives are the raw materials for manufacturers of sandpaper and gauze;

6. Functional fillers - mainly used for automobile brake parts, special tires, special building products, etc. It can be used as wear-resistant materials for building highway roads, airstrips, docks, parking lots, industrial floors, sports venues, etc.;

7. Filtration medium - is a new application field of abrasives. Granular abrasives are used as the bottom medium of the filter bed to purify drinking water or waste water. It is a new type of water filtration material at home and abroad, especially suitable for non-ferrous metal mineral processing: oil drilling mud weighting agent :

8. Hydraulic cutting - using abrasives as the cutting medium and relying on high-pressure hydraulic jets for basic cutting, it is applied to the cutting of oil (natural gas) pipelines, steel and other components. It is a new, environmentally friendly and safe cutting method.

APPLICATION AREA

Oil Pipeline

Oil Pipeline

Steel Plate

Steel Plate

Casting

Casting

Aerospace

Aerospace

Car

Car

Ship

Ship

Steel Structure

Steel Structure

Casting

Casting

RELATED PRODUCTS

GET A FREE QUOTE

To: Shandong HengSin Industry Produts Co,Limited