PRODUCT CENTER

CONTACT US

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

Mobile

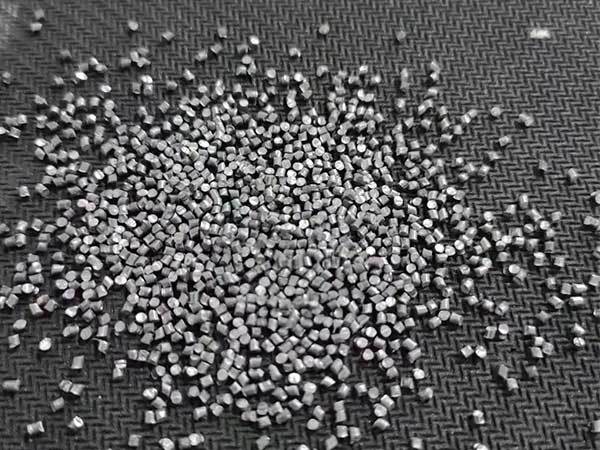

Steel ball S130

Classification :

key word : Grinding pellets

Product Details

Product Details

Characteristics of steel shot and steel grit: moderate hardness, strong toughness, impact resistance, can be used repeatedly for several times, long life, good resilience, strong adhesion, fast cleaning speed, low sand consumption, no broken, high brightness of cleaned workpiece, technical effect Yes, the cleanliness of metal surfaces treated by this product can reach international standards. The surface roughness reaches 25--100um, which increases the contact surface of the metal surface, improves the surface adhesion of the smear, and strengthens the metal structure of the refined metal surface, which has very significant economic benefits. Ideal for cleaning blasting, descaling and strengthening of high-quality materials. Main properties of steel shot and steel grit:

National standard steel shot: GB/T18838.3-2008

Product Parameters

|

Products |

Cast steel shot |

|

|

Chemical composition |

C |

0.80-1.10% |

|

|

Mn |

0.60-1.20% |

|

|

Si |

0.50-1.20% |

|

|

P |

≤0.03% |

|

|

S |

≤0.03% |

|

Hardness |

Normal:40 ~ 50HRC (377 ~ 509HV) |

|

|

Hardness Deviation |

Max deviation3.0 HRC or40HV |

|

|

Density |

≥7.50g/cm3 |

|

|

Durability |

2200 to 2500 times |

|

|

Microstructure |

Homogeneous tempered martensite or troostite |

|

|

Mesh |

25-35 |

|

|

SAE |

Application |

|

S-780 S-660 |

Knock-out or descaling large cast iron, cast steel, iron pipe, forged piece and heat treatment piece. |

|

S-550 S-460 |

Knock-out, descaling, peening and shaping of medium-to-large cast iron, cast steel, forged piece, heat treatment piece, steel plate and pipe. |

|

S-390 S-330 |

Knock-out, descaling, peening and shaping of small-tomedium cast iron, ductile iron, cast parts, heat treatment piece, steel |

|

S-280 |

Blasting small cast iron, cast part, heat treatment piece, cast aluminum, cast steel plate and cast copper alloy before gold-plating process to increase elasticity and toughness. |

Metallographic structure: tempered martensite, tempered troostite, reticulated carbide > grade 3 Hardness: 45---65HRC Density: 7.5cm3

Detailed description:

Features of steel shot: moderate hardness, strong toughness, impact resistance, can be used repeatedly for several times, long life, good resilience, strong adhesion, fast cleaning speed, low sand consumption, no broken, high brightness of cleaning workpiece, good technical effect, The cleanliness of metal surfaces treated by this product can reach international standards. The surface roughness reaches 25--100um, which increases the contact surface of the metal surface, improves the surface adhesion of the smear, and strengthens the metal structure of the refined metal surface, which has very significant economic benefits. Ideal for cleaning blasting, descaling and strengthening of high-quality materials.

Applications

Sand blasting is mainly used for the surface treatment of metal products such as steel, and steel shot blasting is mainly used for the following applications:

1. Workpiece coating and pretreatment sandblasting for workpiece bonding can remove all dirt such as rust on the surface of the workpiece, and establish a very important basic schema (that is, the so-called rough surface) on the surface of the workpiece, and can pass Swap abrasives of different particle sizes to achieve different degrees of roughness, which greatly improves the bonding force between the workpiece and paint and plating. Or make the bonding parts more firm and better in quality.

2. Cleaning and polishing of the rough surface of castings and forgings and workpieces after heat treatment

All dirt (such as oxide skin, oil and other residues), and polishing the surface of the workpiece to improve the smoothness of the workpiece, can make the workpiece exposed

It can produce a uniform and consistent metal color, make the appearance of the workpiece more beautiful, and achieve the role of beautification and decoration.

3. Burr cleaning and surface beautification of machined parts Sandblasting can clean the tiny burrs on the surface of the workpiece and make the surface of the workpiece more

Flattening, eliminating the harm of burrs and improving the grade of the workpiece. And sandblasting can make small rounded corners at the junction of the workpiece surface, making the workpiece more beautiful and more precise.

4. Improve the mechanical properties of the parts. After the mechanical parts are sandblasted, they can produce uniform and fine concave-convex surfaces on the surface of the parts (base

Basic diagram), so that the lubricating oil is stored, so that the lubrication conditions are improved, and the noise is reduced and the mechanical service life is improved.

5. Lighting effect For some special-purpose workpieces, sandblasting can achieve different reflections or matts at will. such as stainless steel T

Parts, wood furniture surface matt, frosted glass surface pattern pattern, and cloth surface texture processing, etc.

APPLICATION AREA

Oil Pipeline

Oil Pipeline

Steel Plate

Steel Plate

Casting

Casting

Aerospace

Aerospace

Car

Car

Ship

Ship

Steel Structure

Steel Structure

Casting

Casting

RELATED PRODUCTS

GET A FREE QUOTE

To: Shandong HengSin Industry Produts Co,Limited